Hey

For some time I have been interested in 3D printers, I wasn’t convinced to FDM method of production at first, but after I have seen and held a 3D printed object I noticed it is quite strong and reliable if printed correctly.

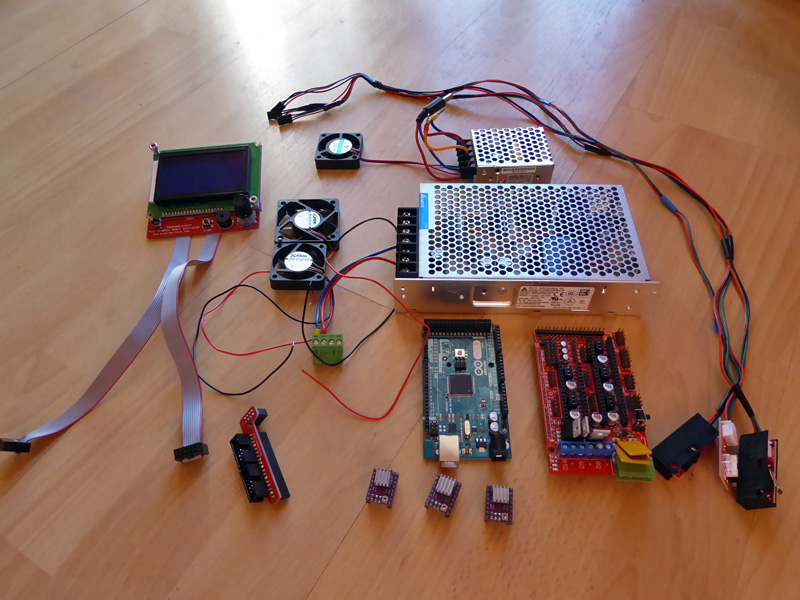

Hence I decided to have a 3D printer of my own. Because I didn’t have enough time to create one, together with my bother we bought a second-handed printer. Unfortunately printing head in bought machine wasn’t of good quality, all shabby and temporary, also fans for cooling the print weren’t working and it was difficult to print anything. I think that there was no point to try to repair old head, so I had to create a new one.

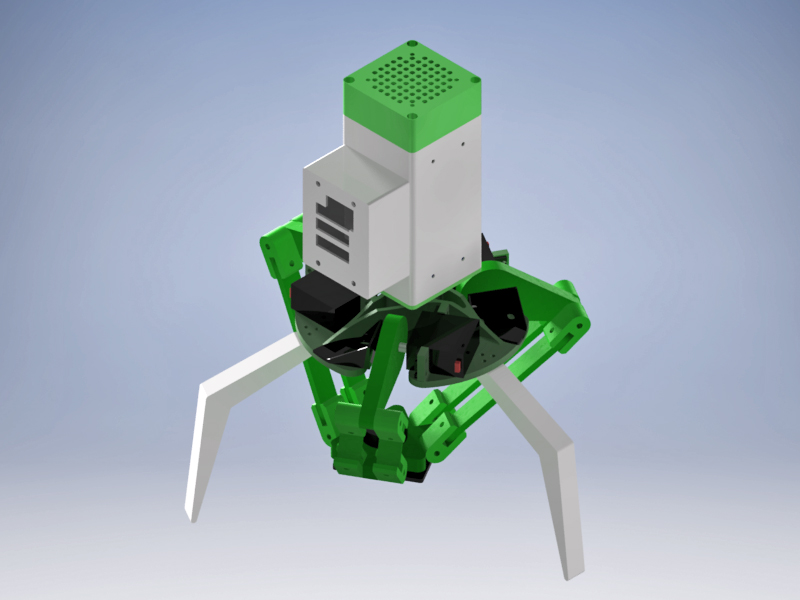

I wanted the head to have two separate extruders so I bought premade hot ends, and decided that the whole construction will be created from 10mm thick aluminum (mostly because I had some leftovers of it from other projects), I had to fit my head correctly to dimensions of bought machine so I stared with 3D model. There are no fans and some other details (nuts, screws) on the model, I also used already made NEMA 17 stepper motor model (source).

After the model was finished my CNC milling machine started its job 🙂 Most of the milling was done using 5 mm endmill with two flutes designed for aluminum.

It took few hours to mill the parts, I had to tap few holes, and correct few dimensions (using my flycutter), because it was too tight of a fit to assemble all the parts. I also added a hole on the main construction plate for all the wires.

When all the parts were finished I started assembling the head 🙂

After the main assembly was done I had to wire it, sometimes guessing which wire is for what, original wires were messed up pretty badly. I also added a terminal block for quick and easy connecting/disconnection wires. And here is my actual working printer head:

I know it is not the prettiest, I may add some kind of cover for the wires and terminal block later on.

With the new printing head I started setting up the machine, I tuned the hot ends PID regulators settings, and corrected the zero position. I also leveled the printing table and it was ready for printing.

For my first prints I decided to create some calibration cubes (source file below) with different settings so I can choose the basic print settings for PLA material and I can print some more advanced stuff (even a shelf for my TV PC) 🙂 (source files of used models below)

There is still a lot to correct, I hope my prints will get better eventually 🙂 but for most of my needs this printing precision is enough. Now I have to try printing some stuff from ABS, so probably more printing posts are coming soon 🙂

Stay Sharp!

Source files for used 3D models:

– 25mm calibration cube with empty top

– propeller vase

– Standing figure of Alex

– Flame vase 2

.